Item Number:

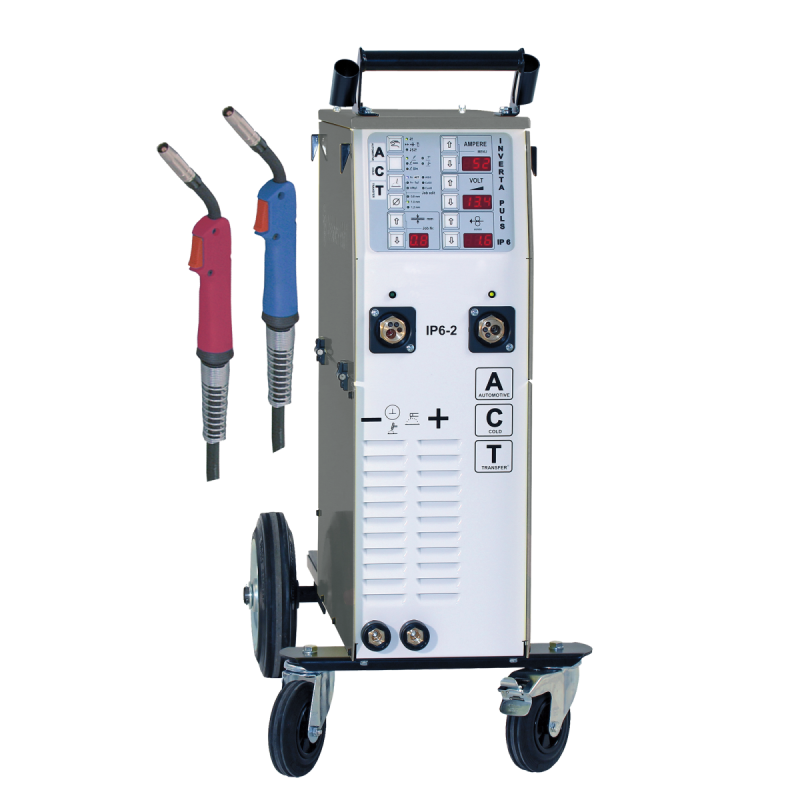

• MIG/MAG welding – MIG brazing

• 4-roller drive with fine adjustment, wire speed 1.5-15 m/min.

• Holder for D300 coil (max. 17 kg)

• Display with hold function for welding current and voltage

• Dynamic adjustment – end pulse to detach the ball at the end of the wire

• Good welding behavior in the thin sheet range (0.6 mm steel welding)

Welder with inverter technology. A very straight forward and simple to use machine with simple settings because of the tough construction – it will tolerate very hard impacts.

• MIG/MAG welding (MIG-flux-cored welding wire brazing)

• 4 roller drive with trim adjustment

• use with D300 wire spool (max. 17 kg)

• display with hold function for welding current and tension.

• dynamic pulse adjustment to remove the „ball“ at the end of the wire

• extremely good welding results even on very thin sheet metal. There are no problems with steelwelding on panels as thin as 0,6mm (0,023 in)

Item N°: 341290

Packing unit: 1 pc.

Open-circuit voltage: 40,2 V

Net weight: 46.00, 40,000 kg

Temperature range: -40°C to +80°C

Voltage range: 10-35 V

Power factor: 0.75

Efficiency: 87%

Temperature class: H (180°C)

Fuse: 16 A

Continuous output: 0,12 kA / 20 V

Supply voltage: 230 V (+10/-15%)

Continuous operation: 20%/ 0,2 kA / 24 V

Certificatons: CE

Setting ranges: 0,020 – 0,200 kA

Working temperature: -10 to +40°C

LängexBreitexHöhe: 900x500x840 mm

Gross weight: 53,000 kg, 48.00

Specifics: Ø wire-drive spools 37 mm

Lenght: 3 m (distiller pack)

Power supply (Cu): 3×2,5 mm²

Protecton category: IP23

1x Control unit IM 240-i incl. castors

1x Gas bottle debice

1x Torche MB15 3m for steel with wire-guiding spiral

1x DV rolls for steel 0,8/0,6 mm

1x Ground cable 4 m

1x User’s Guide